When Experience Matters, Think Perma-Fix

Learn more about our services and capabilities

What makes Us Different

We have a solid reputation of successfully completing complex nuclear and waste management projects. Our knowledge and experience of operating our own large waste treatment facilities together with the experience in the areas of project management and technical services, has allowed Perma-Fix to expand into a global nuclear services company.

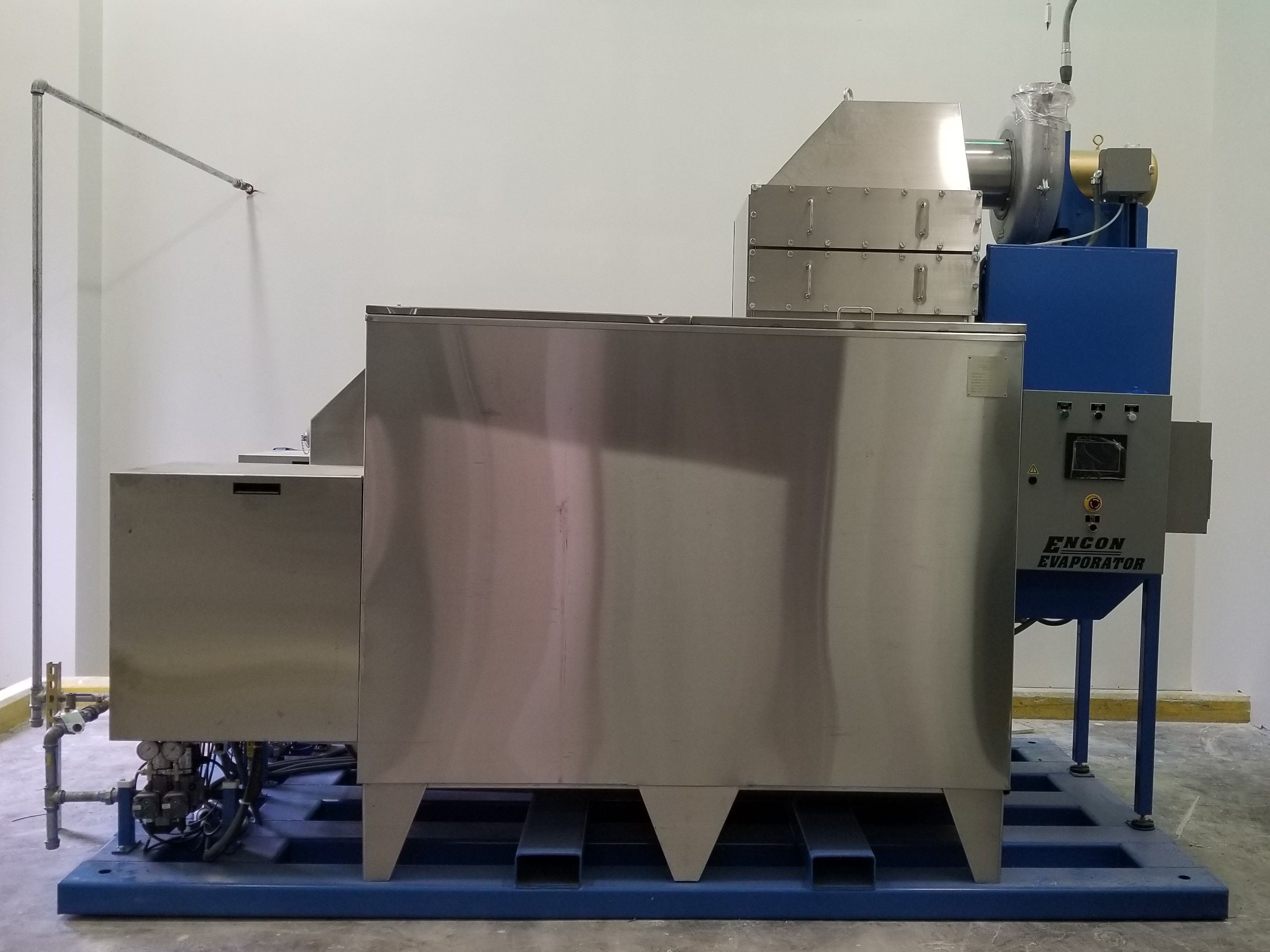

Waste Treatment Facilities

Our waste treatment facilities are located across the US and we possess licenses, permits, and expertise to treat a wide variety of waste streams.

.Upcoming Events

-

April

18

-

April

24Demo MACC Industry Day

-

June

4-5DOE Small Business Forum and Expo.

Booth 819